FINISHING

-

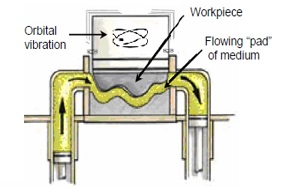

ABRASIVE FLOW MACHINING

Ideal for smoothing & finishing I.D. surfaces that may be difficult to otherwise process

-

ASSEMBLY

The ability to handle 2-piece assemblies to complex projects complete including material, off-the shelf components, machined components, special processes, assembly & test

-

BEAD BLASTING

Custom design of nozzles to meet any sand-blasting or bead-blasting needs

-

DEBURRING

Highly-trained staff to customize the deburring process to your specific part requirements

-

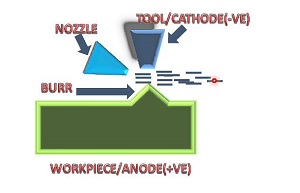

ELECTRO-CHEMICAL DEBURRING

To remove burrs from hard-to-reach cross-hole intersections

-

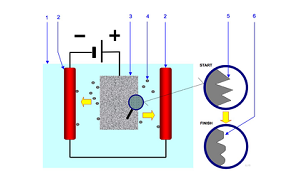

ELECTROPOLISHING

An electrochemical process that removes material from a metallic workpiece to polish, passivate, or deburr metal parts

Multiple E.P. lines to meet your electropolishing needs

-

HONING

The ability to achieve bore sizes in the ±.0001 tolerance range and verify size and roundness using special metrology equipment

Multiple hones to meet your honing needs

-

PART MARKING

Laser marking

CNC engraving

Hard stamping

Ink marking

Electrochemical etching

Dot peening

-

POLISHING

Polishing lathes, polishing mills & hand polishing capabilities to achieve the desired part surface finish

-

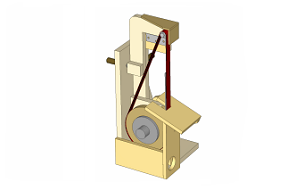

SANDING/TEXTURIZING

Both automatic & manual sanding/texturizing equipment to achieve the desired part finish

-

TESTING

Balance testing

Burst/Failure testing

Flow testing

Force testing

Hardness testing

Pressure testing

Torque testing

XRF testing

-

VIBRA-DEBURRING

Multiple tumbling machines and various media to meet your part finish requirements

-

WASH SYSTEMS

Multiple ultrasonic wash lines to meet your part cleaning requirements